-

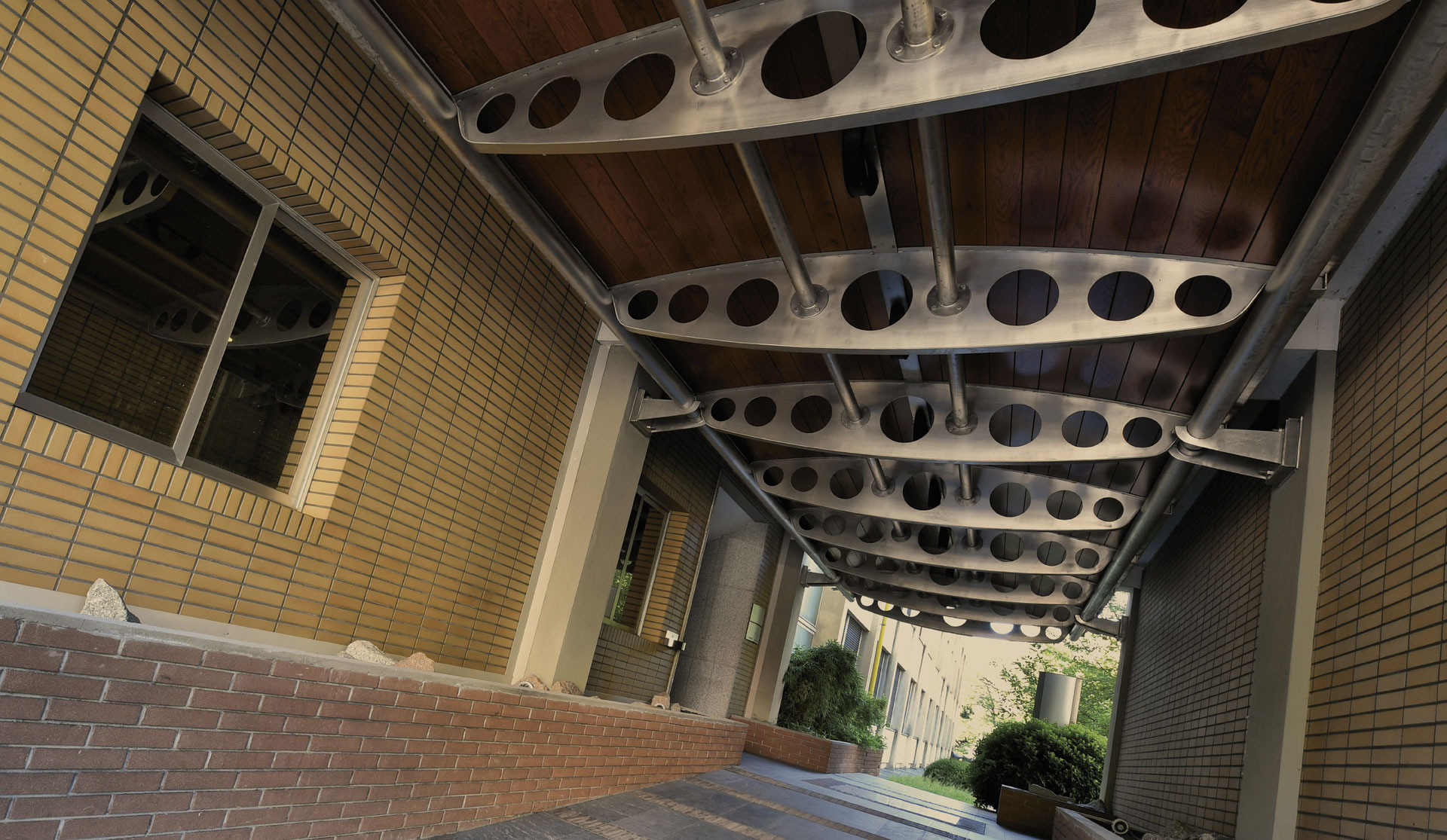

BEFORE PRODUCING

BEFORE PRODUCING

A HIGH QUALITY COFFEE MAKER

IT IS IMPORTANT BEING ABLE TO IMAGINE IT

-

OUR HISTORY DATES BACK TO THE 90's

OUR HISTORY DATES BACK TO THE 90's

WITH DEVELOPMENT AND INDUSTRIALIZATION OF PROJECTS AMONG THE MOST INNOVATIVE

IN THE COFFEE MAKERS INDUSTRY -

WE HAVE BEEN WORKING

WE HAVE BEEN WORKING

IN COLLABORATION

WITH THE MOST IMPORTANT

BRANDS IN THE SECTORFor more than 10 yearsfocusing on the entire supply chain of the coffee makers production -

SUPPLY OF CUSTOMIZED COFFEE MAKERS

SUPPLY OF CUSTOMIZED COFFEE MAKERS

A long way to become today, one of

the most experienced italian companies in theGiuseppe Nerozzi

01.

PLANNING STAGE

Do you expect excellence in a coffee maker? Do you want to give a distinctive mark on production in order to be different from your competitors …

02.

MANAGEMENT STAGE

To reach a leadership position in the coffee makers industry, particular attention must be paid to the management stage. Years of experience…

03.

PRODUCTION STAGE

After studying market dynamics and defining product specifications, we are quality guarantors with stable and systematic supervision…

Giuseppe & Paolo Nerozzi

Experience and professionalism since 1962

Since 2004

we are protagonists of

innovative projects

Working method

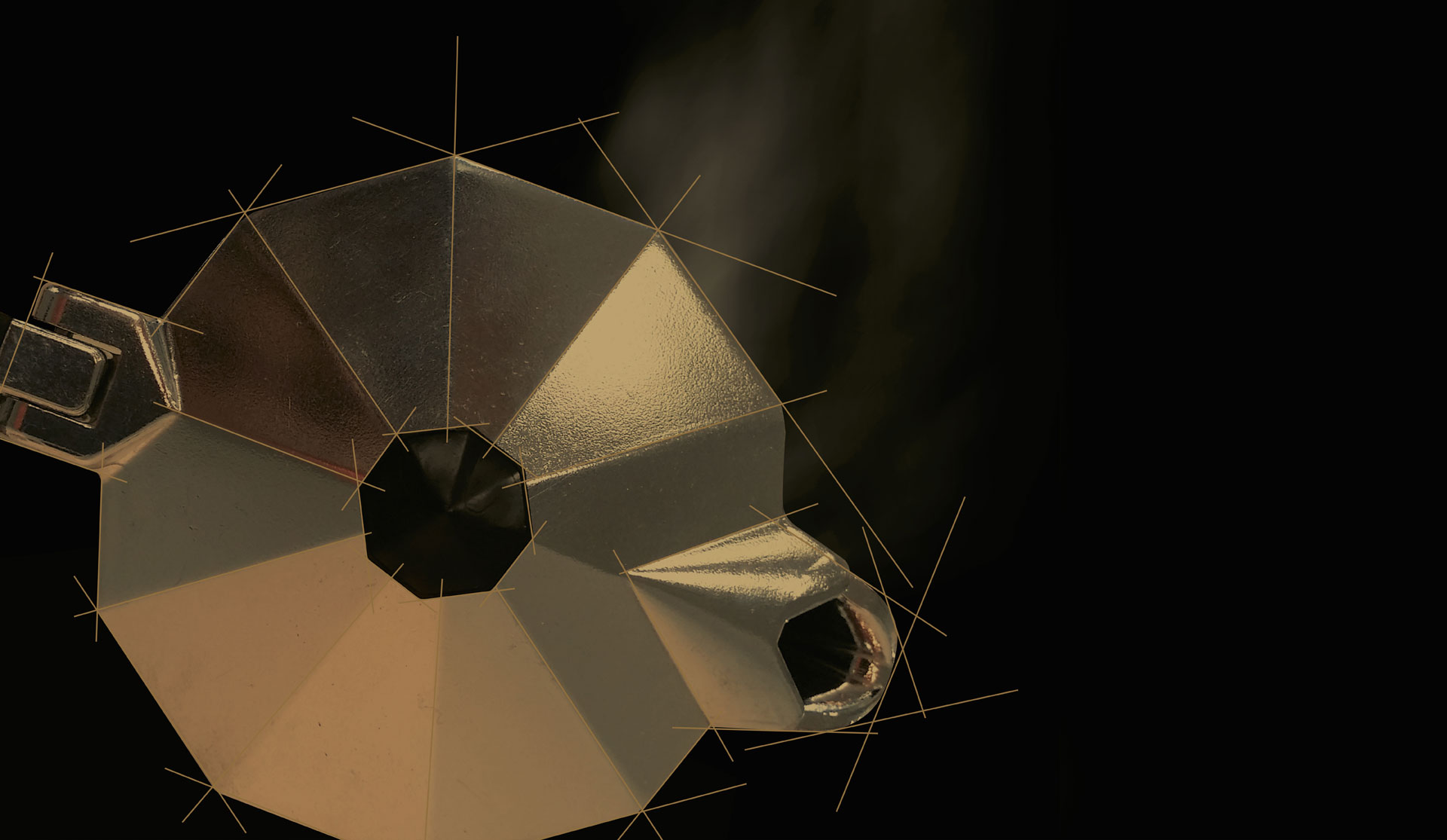

GALNER follows the whole production chain of coffee makers and does so with precision, accuracy and flexibility to meet the needs of demanding customers. Its philosophy is based on the excellence of form, safety, respect for the environment, health and the needs of the final consumer. Particular attention is paid to the selection of materials complying with European food standards, but not only. To have a good coffee maker, it is imperative to properly proportionate the internal volumes, in accordance with the thermodynamic principles, which determine the quality characteristics of the extracted coffee, verified with documented sensory analysis.

Using only suitable aluminum alloys for food use according to EN 601-602 and European legislation, guaranteed to the origin by means of chemical analysis certificates for each single supply.

Gripping devices and designed couplings, manufactured and tested according to EN13248; Static load “5 times its weight”;

“Endurance” resistance to fatigue, 7,000 cycles.Robustness warranty in case of improper use is provided through the “In process” control of material thickness, weight of the components and compliance of manufacturing and assembling and systematic auditing at the deliberation stage of each supply.

We provide certification of suitability for parts made in rubber in contact with food, according to the European and American legislation (FDA 21 CFR 177.1210)

They are regulated by a grid of tests/checks, as to guarantee for all the products safety and regular functionality. The grid can be suitably implemented according to the needs of the customer to satisfy the different market positions (from the middle to the top of the range). Each supply is subject to audit and is characterized by the documented quality indicator “IMQ”.

Quality is guaranteed through controls which verify compliance with: Finished Product Specifications (Norma EN 13248); Food Specifications (Standards EN 601 and 602); Working Specifications (2D Drawings of the Details); Technical specifications and standards of testing/checking; Standardization of the production stages and purchase components; Reference samples (where the rating is by attributes).

Our strengths

Quality

Experience, knowledge and competence allow us to provide our partners with high-quality products made with attention to the smallest details…

Flexibility

We are attentive to the market dynamics, from new products to new distribution methods. We are flexible and we work for customer satisfaction…

Assistance

We are a highly specialized company. Our knowledge is based on thousands of hours of experimentation on the product…

Our history starts from afar, with the development and industrialization of some of the most innovative coffee makers projects in Italy from the ’90s onwards. For over 10 years we have been working with the most important brands in the sector, dealing with the entire production chain for the production of coffee makers. A long journey that leads us to become today one of the companies in Italy with more experience in the industry, thanks also to important partnerships with leading Chinese manufacturing companies.

Our work has been enjoyed daily since 2004

News

Contacts

Address

Via 42 Martiri, 165 – 28924 Verbania (Vb)

Telephone

+39 349 7640466 / +39 393 8377740